- 901-598-7979

- Mon - Fri: 8:00 am to 5:00 pm

Unfortunately, this is far from a perfect world so when things don’t go well, you need someone you can trust to make things right.

Advanced Garage Door specializes in both NEW residential and commercial garage door installations as well as existing garage door repairs.

Our promise is that we make sure your garage door functions at 100% when we fix or install it, and we also make sure it looks neat and clean while doing its job.

Call us today to schedule an appointment for an estimate.

A new garage door can make a huge difference in the way your home looks, inside the garage and outside.

We offer a wide selection of garage door models, even more design options, and many stock or custom colors for you to choose from. If a custom garage door is something you fancy, we can do that too.

We can also install a new garage door opener when you upgrade your existing garage door, for a completely new garage door system. But remember a new opener is not necessary with a new garage door unless yours does not work.

I take great pride in being able to repair residential and commercial garage doors that others said need to be replaced. Not everything can be repaired but a lot can be if you have Advanced techniques (also a hammer; lots of extra screws and serrated lock nuts; rivets;😆 And you're not lazy.)

If your garage door is damaged, or just won’t open, let us help you get that fixed as soon as possible.

Garage door sections can be replaced or repaired/reinforced and many other parts can be replaced depending on wear.

Give me a call to schedule an appointment or to discuss the problem you are having.

Your business typically has special requirements when it comes to it’s garage door system.

Hi-lift, vertical lift, follow the roof pitch, electric motors designed for hi cycle applications, and industrial strength are just a few of these special needs. We carry a wide selection of commercial style garage doors with the options that you need.

We are experienced with them all and are confident in the value our products will add to your business.

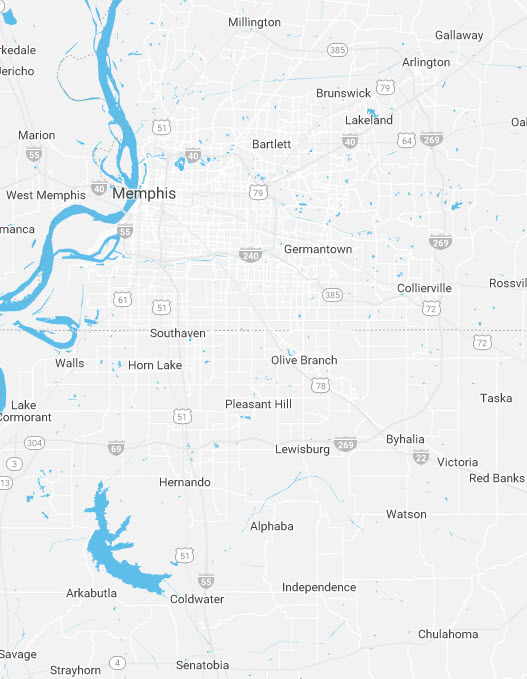

<Look a map! Maps are great! Since we fix garage doors everywhere on this map we’re the closest garage door service to you! How convenient!

We are proud to provide excellent garage door service to the greater Memphis area.

Service Areas:

Southaven, MS / Memphis, TN / Olive Branch, MS /Horn Lake, MS / Collierville, TN / Bartlett,

TN / Walls, MS / Nesbit, MS / Hernando, MS / Germantown, TN / Cordova, TN / Lakeland, TN /

Arlington, TN / West Memphis, AR / Marion, AR / Byhalia, MS / Millington, TN / Coldwater, MS